The 6-Minute Rule for Fan Clutches

Table of ContentsSome Known Facts About Fan Clutches.A Biased View of Fan Clutches

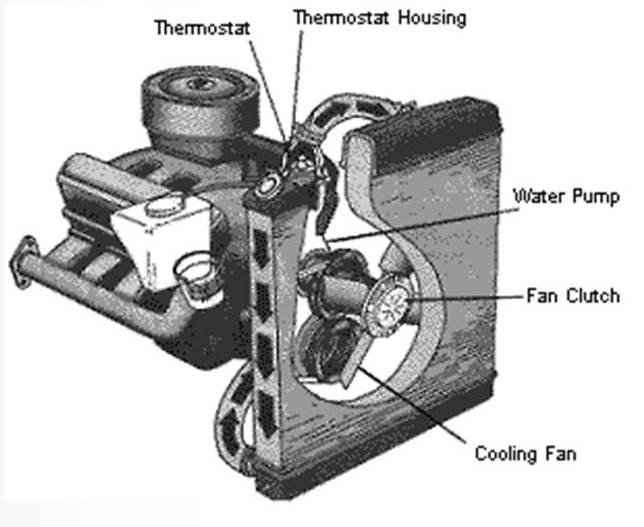

A thermal fan clutch is engaged on a cold start-up due to the fact that the fluid drains into the workspace when the engine is turned off. The fan clutch will slow down shortly after start-up as an outcome of a pumping action produced by a difference in speed between the shaft and the body of the clutch.Some Chevrolet/GMC truck models are particularly developed to engage at lower temperature levels than the initial equipment parts that they replace. Hayden makes 3 different kinds of thermal fan clutches; Standard, Heavy and Serious Duty. Each type is crafted to simulate the efficiency, fit and appearance of the initial devices clutch that it replaces.

of working surface. Recognized by a smooth steel faceplate & thermal spring assembly on the front side. Turns the fan 80-90% of the shaft speed when engaged for increased cooling. Turns the fan 20-30% of the shaft speed when disengaged. Utilized with much deeper pitch fans. (2 -1/ 2" of pitch). Land and groove style with 26.

In. of workspace allows higher operating RPM's. Determined by finned aluminum faceplate and thermal spring on the front. Turns the fan 80-90% of the shaft speed when engaged. Turns the fan 20-30% of the shaft speed when disengaged. Utilized with much deeper pitch fans. (2 -1/ 2 of pitch). Land and groove design with 70 Sq.

Things about Fan Clutches

GMB is an OE bearing maker with over 70 years of experience. With this expertise, GMB Fan Clutches boast unparalleled quality featuring the GMB bearing. fan clutches. With click here now comprehensive protection and constant expansion, the GMB Fan Clutch program will satisfy the needs of every consumer. 100% Performance and Toughness evaluated Designed with OE production innovation Minimized warm up time Optimized engine efficiency Genuine GMB bearing Improved fin style for maximum heat dissipation Decreased fan sound and vibration throughout acceleration or travelling Thermal (viscous), Non-Thermal and Electric Fan Clutch available Requirement, Strong, and Severe Task versions readily available.

Select Year 2012Â 2011Â 2010Â 2009 2008Â 2007Â 2006Â 2005 2004Â 2003Â 2002Â 2001 2000Â 1999Â 1998Â 1997 1996Â 1995Â 1994Â 1993 1992Â 1991Â 1990Â 1989 1988Â 1987Â 1986Â 1985 1984Â 1983Â 1982Â 1981 1980Â 1979Â 1978Â 1977 1976Â 1975Â 1974Â 1973 1972Â 1971Â 1970Â 1969 1968 1967 Select Make Select Model Select Sub-Model Select Engine Filter Outcomes. Multi-Wing, the leading supplier of high-performance axial flow fans, is a single source for fan and fan clutch systems. The viscous clutches are either electronically controlled or air sensing by means of bi-metal sensor. Off-highway and stationary equipment, consisting of ag tractors, skid steers, excavators, building equipment, pavers, articulated dump trucks and power generators Responsive, professional engineering support Provides fuel cost savings Substantially decreases noise Broad modulation variety Low off speed Flexible mounting alternatives Reduces cooler clogging Upkeep complimentary with a long operating life. When labor is accounted into the overall fan clutch replacement cost, the total anchor price can range in between $285 to $500 to change the fan clutch just. In order designs, the fan clutch is frequently entirely controlled by the temperature level of the engine in contrast to the engine speed. As the clutch heats up and the friction gets stronger, the parts within the engine can rub versus each other and develop up more heat.

When the fan clutch cools off, the engine fan decreases due to the decrease in the amount of friction produced within the engine. fan clutches. This, nevertheless, can differ spending on the engine speed reducing or increasing unexpectedly. As the state of the clutch modifications, this identifies how quick or how slow the fan is article able to speed up or slow down during usage.

Electronically managed fan clutches operate in the same method, but they are managed by a control module rather of a mechanical piece. The fan clutch supervises of spinning loosely till the temperature reaches a certain level, at which point the fan clutch will completely switch on and engage so that the fan can operate at the highest performance and performance level.

There are certain signs and symptoms that can reveal you how often you will require a fan clutch replacement and give you an overall idea of just how much the price will be for the fan clutch replacement expense. One of the very first signs and signs that is usually connected with a bad or stopping working fan clutch is an overheating engine.

If the fan clutch is not working or not engaging correctly at all, this can disable the fans or prevent them from working at the ideal level and working at optimal effectiveness. This may result in the engine overheating, which can result in additional concerns and a more expensive fan clutch replacement cost in time and if left unattended.